Design and manufacture of various filters and industrial dust collectors

Shokoofa Sanat Pouya Company, with the aim of expanding its activities in the fields of environment and pollution control, has been able to take effective steps towards the development of our beloved homeland in this field. The company by adding some equipment and machinery to make key parts, readiness to design, engineering, supply, installation and commissioning of this equipment based on up-to-date knowledge in this field in the world and relying on internal capabilities along with quality Unparalleled in the country and abroad.

Products and services in the field of industrial filtration and dust collectors

Design and manufacture of high efficiency electrofilters (ESP) in various industries

ELECTROSTATIC PRECIPITATOR is one of the most practical and rigid dust collectors in various industries that can operate in different conditions. This type of dust collection system is recommended in cases where the use of other systems is not economical or possible.

Advantages:

- Economic cost of supply

- Low operation, maintenance costs

Optimal dusting efficiency up to 20 mg / Nm3 and sometimes less

- Heavy Duty for difficult industrial applications

- Less occupied space with high absorption technology

Industries used for electrofilters:

Cement, copper, alumina, steel, pelletizing, wood and paper industries, waste fuel furnaces, zinc, zinc, chromium, nickel, etc. industries.

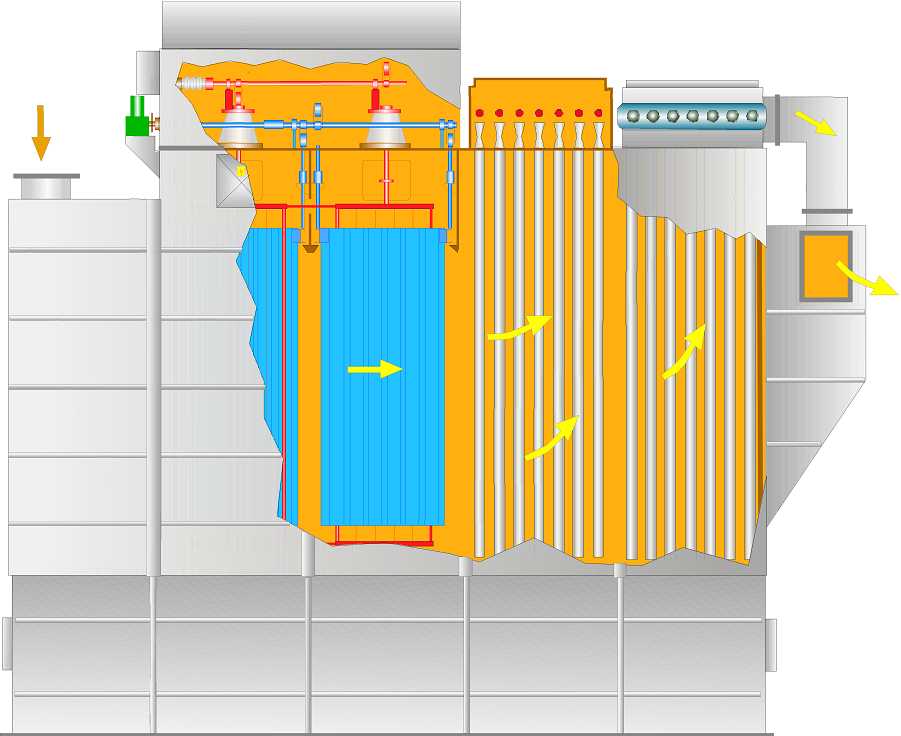

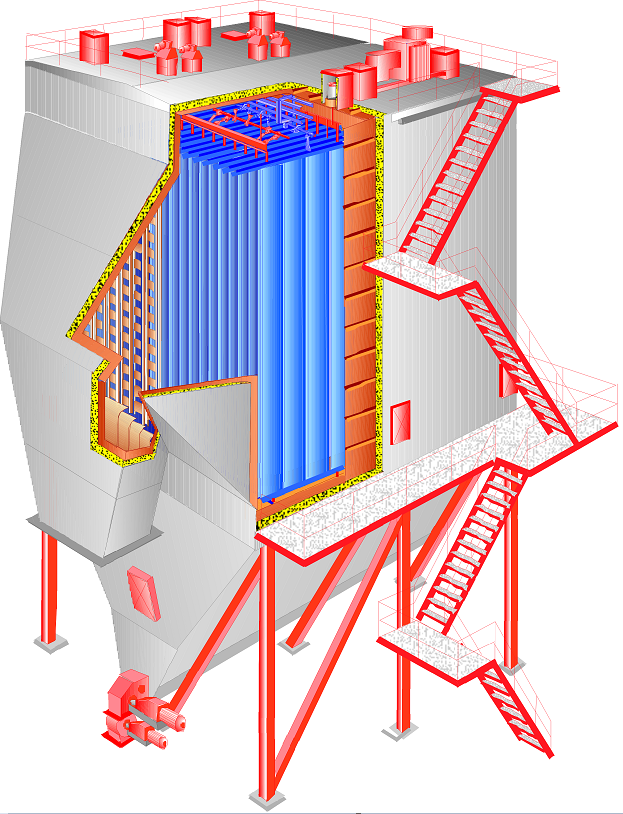

Description of electrofilters:

Creating a strong electric field between the electrodes (negative pole) and the ground-connected separating plates (positive pole) causes the input particles to be adsorbed on the separating plates after charging (during the "corona" ionization operation). Then, by applying the desired mechanical force, the dust collected on the surface of the absorption plates (Dust Cake) due to the force of weight, is poured into the lower hopper (Hopper) and is moved by dust transfer systems.

Design and manufacture of bag filters

Bag filters are a type of dust collection system that collects particles in the dust gas for various applications behind the fabric filter (Filter Bag). These dust collectors have bags with fabric materials with various specifications that the choice of material depending on its use is very important. Bag filters are used to filter and purify various gases containing particles with different properties and sizes in order to achieve a very high efficiency in cleaning, which in case of optimal design, the dusting efficiency will increase to a very desirable level.

Advantages:

- Less manufacturing weight

- Minimal space occupation if using long bag technology

- Dust output up to 5 mg / Nm3

- Higher reliability than other methods

Industries used:

Cement, mining, steel, copper, textile, aluminum, food industries and all small and large manufacturing industries

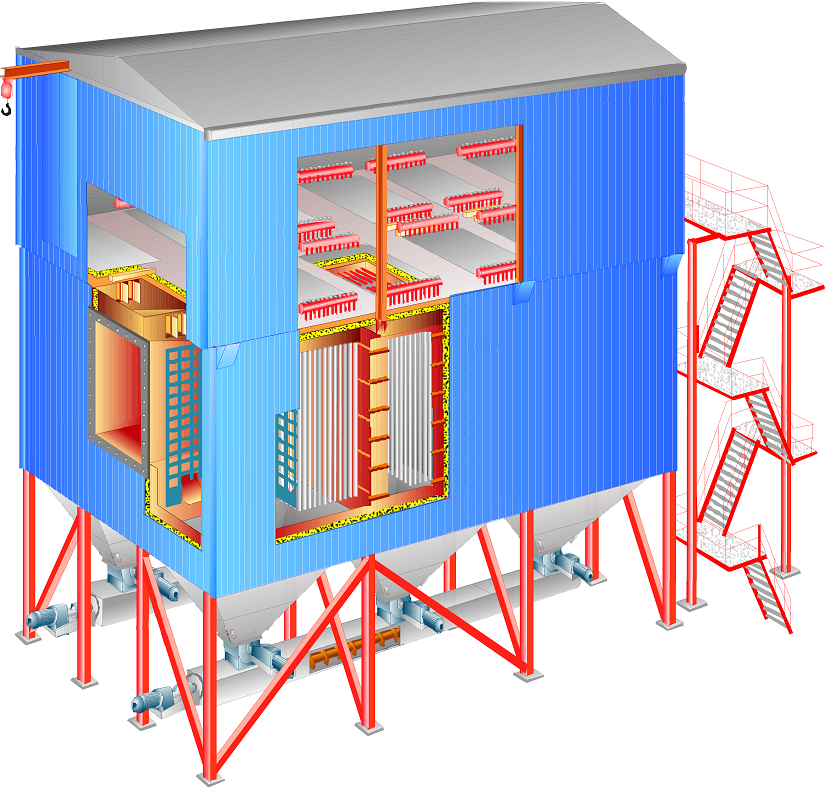

Design and manufacture of hybrid filters in various industries

This equipment, which is a combination of electrofilters and bag filters, is recommended for industries that require a very high level of efficiency or that, due to environmental regulations, need to optimize their current dust collection system without changing their Foot Print.

In this equipment, two dusting methods are used to absorb particles. Larger particles are absorbed by the electrostatic precipitator and smaller particles are adsorbed by the bag filter, which increases the relative efficiency of the dust collection systems compared to the cost.

The use of hybrid filters will also increase the life of bag filter equipment (bags and baskets).